Digital textile printing

Why are we committed to digital textile printing?

Nowadays digital textile printing is the last trend in the market because it promotes efficiency, agility, and profitability in the textile production.

Digital textile printing can be differentiated for different reasons:

- Compared to other techniques digital printing requires fewer steps to set up in terms of production.

- Moreover, it should be noted that digital printing is ideal for producing small quantities.

- In terms of color there are no limits since the technique can print any color and the combination of these.

What are the benefits of digital textile printing?

Currently, we know that traditional printing process are not very ecological. Therefore, in recent years a more sustainable textile printing has been sought, with less pollution and at the same time less expensive.

The inks used in traditional printing technique, such as serigraphy printing, are highly polluting. In addition, for the traditional process printing are needed large amounts of ink and water.

In the case of digital textile printing, it uses other environmental methods that reduce the amount of water and ink needed since it is injected onto the fabric.

The fabrics used by luzdeseda are with water-based inks with the STANDARD 100 certificate of OEKO-TEX 100 (class 1).

Digital textile printing can also mean better inventory planning, which translates into less overstock and reduced storage needs.

Therefore, digital textile printing is changing the traditional textile business model, driven by the growth of sales on demand production.

Variety of designs with a multitude of colors?

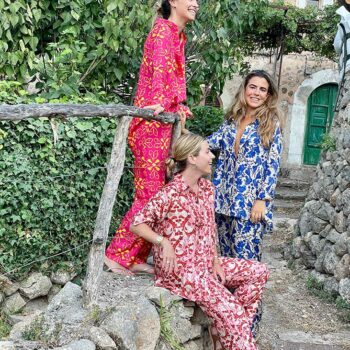

On the contrary techniques such as serigraphy the use of colors is limited, however, the digital textile printing has the advantage of printing complex prints with great details without restriction in the range of colors.

At luzdeseda we have 8 types of silk fabric and one voile wool.

- Twill 12mm

- Twill 14mm

- Satin 16mm

- Crep 14mm

- Habotai 8mm

- Habotai 5mm

- Chiffon 5mm

- Georgette 10mm

- Voile wool 90gr/mt

All the silk fabrics and the voile wool are 100% natural and have a with of 140cm. All our fabrics maintain a soft touch once the printing process is finished.

The process is entirely made in Spain.